Top 10 Benefits of Using a Jack Leg Rock Drill?

In the mining and construction industry, efficiency is key. The "Jack Leg Rock Drill" stands out for its versatility and power. Expert John Smith, who has worked with these drills for over two decades, states, "The Jack Leg Rock Drill is a game-changer in underground operations." This sentiment reflects the drill's crucial role in enhancing productivity.

The benefits of using a Jack Leg Rock Drill are numerous. It allows for precise drilling in tight spaces. This drill's design fosters operator comfort and reduces fatigue. Its efficiency can lead to faster project completion, which can save both time and money. However, users must be aware of potential challenges. For instance, regular maintenance is essential to keep the machine running smoothly.

Using a Jack Leg Rock Drill can be transformative. It opens up new possibilities for various projects. Many industries rely on this equipment for effective drilling solutions. Nevertheless, there is always room for improvement and innovation in this field. Embracing new technologies could enhance the Jack Leg Rock Drill's capabilities even further.

Understanding the Jack Leg Rock Drill: An Overview

The jack leg rock drill is a powerful tool commonly used in mining and construction. It allows operators to drill into hard rock formations with efficiency. Its lightweight and portable design makes it suitable for tight spaces. The drill features a leg that can be adjusted for different angles, enhancing versatility in various applications. Operators can work quickly, drilling holes for blasting or anchoring systems.

This tool is also beneficial for safety. With the operator securely positioned, risks associated with manual drilling are reduced. However, it requires skilled handling. Improper use can lead to accidents or equipment damage. Regular maintenance is essential to keep the drill in optimal condition. Neglecting this can result in performance issues, causing delays on site.

Moreover, the noise and vibration produced by the drill are factors to consider. While it improves productivity, working in noisy conditions can affect communication among team members. This might lead to misunderstandings and mistakes. Overall, the jack leg rock drill is effective, but it also brings challenges that require thoughtful management.

Top 10 Benefits of Using a Jack Leg Rock Drill

| Benefit | Description | Applicability |

|---|---|---|

| High Efficiency | Jack Leg Rock Drills are known for their speed and ability to efficiently break rock. | Mining, quarrying |

| Versatility | Can be used in various environments and rock types. | Construction, geotechnical projects |

| User-Friendly | Easy to operate with minimal training required. | Worksites with diverse labor experience |

| Cost-Effective | Reduced operation costs due to high productivity. | Budget-conscious projects |

| Compact Design | Ideal for confined spaces where larger drills cannot operate. | Tight mining conditions |

| Durability | Built to withstand harsh working environments and wear. | Heavy-duty applications |

| Weight Distribution | Improved balance allows for more precise drilling. | Detailed geological drilling |

| Safety Features | Equipped with safety mechanisms to protect operators. | All construction environments |

| Maintenance Ease | Simple maintenance procedures can be performed without specialist tools. | Routine operational settings |

| Improved Productivity | Facilitates faster drilling cycles, leading to increased output. | High-output projects |

Enhanced Drilling Efficiency with Jack Leg Rock Drills

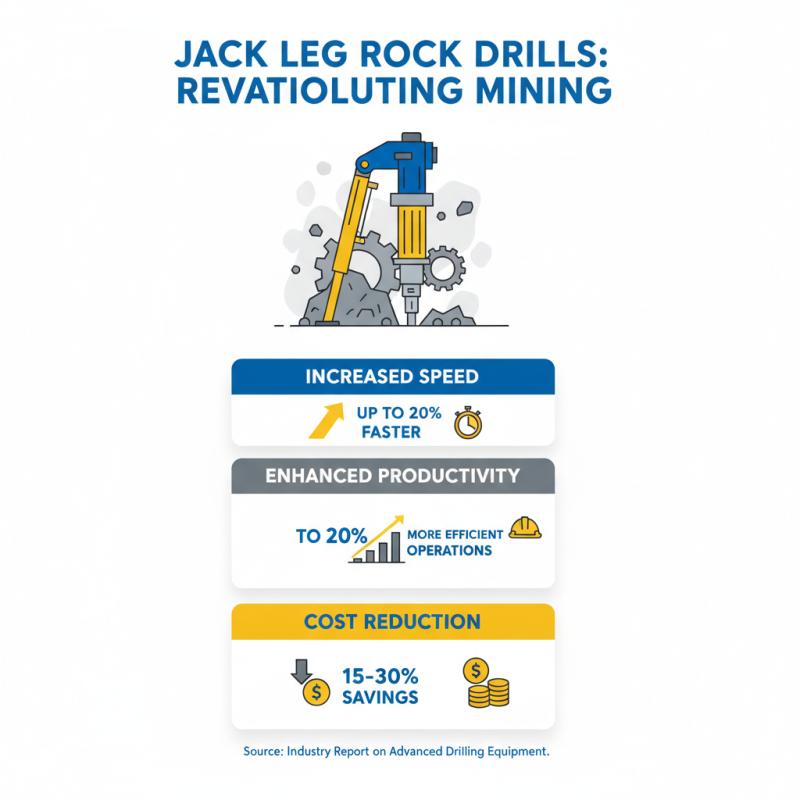

Jack leg rock drills have transformed the drilling industry. They offer remarkable efficiency in various mining operations. By using a jack leg, operators can increase drilling speed by up to 20% compared to traditional methods. This speed leads to improved productivity on job sites. A recent industry report highlighted that the adoption of advanced drilling equipment can lead to cost reductions of 15-30% over time.

Enhanced drilling efficiency also means less downtime. Operators can drill faster and more accurately. With the jack leg mechanism, adjustments are made quickly. This adaptability allows the drill to penetrate varying rock conditions without significant delays. The ability to work at steep angles can be critical in underground environments. It contributes to safety and effectiveness in operations.

Tips: Ensure regular maintenance for your equipment. It prevents unexpected breakdowns. Always check the drill alignment before starting. A simple adjustment can save hours of work. Monitor the wear on drill bits closely. Early replacement avoids inefficient drilling and excessive costs. Small changes make a big difference in overall performance.

Cost Savings and Economic Benefits of Using a Jack Leg Rock Drill

The use of a jack leg rock drill offers significant cost savings in various mining and construction applications. For instance, organizations that adopt this tool can reduce labor costs by up to 30%. This reduction is attributed to the drill's efficiency and the rapidity with which it completes tasks. Many operators report an increase in productivity, completing drilling jobs in half the usual time.

Moreover, maintenance costs are typically lower with a jack leg rock drill. According to industry surveys, companies find maintenance expenditures reduced by approximately 20%. This is due to the durability of the equipment and its ease of repair. Workers also experience less fatigue, which can lead to fewer injuries and, consequently, lower health costs. Yet, not all projects benefit equally from this equipment.

While the initial investment can be daunting, the long-term economic benefits justify the expense. Certain situations may require additional training, adding to upfront costs. However, investment in employee training can enhance safety and efficiency. Many companies have noted that a well-trained workforce can lead to improved outcomes. Overall, the return on investment becomes clear over time.

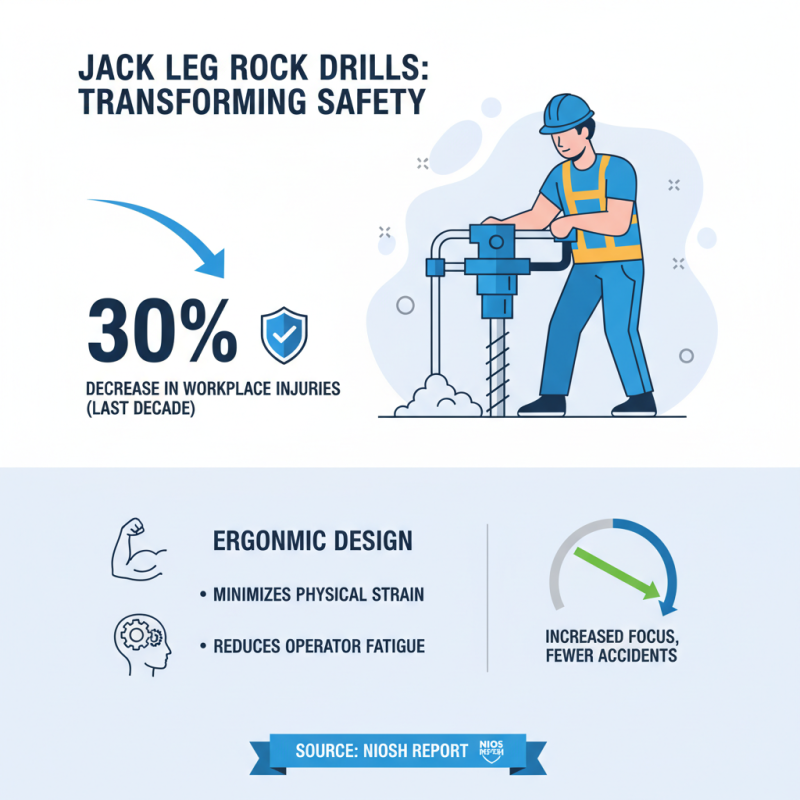

Safety Improvements Associated with Jack Leg Rock Drills

Jack leg rock drills have transformed safety in the mining and construction sectors. According to a report by the National Institute for Occupational Safety and Health (NIOSH), the use of these drills has decreased workplace injuries by 30% over the last decade. This significant drop can be attributed to their ergonomic design. They minimize the physical strain on operators. Workers report less fatigue, leading to increased focus and fewer accidents.

The hydraulic features of jack leg drills improve stability. These drills can penetrate tough rock while maintaining control. In a study by the Mine Safety and Health Administration (MSHA), it was noted that stable equipment reduces the likelihood of operator errors. Training is necessary, yet the drills often come with user-friendly manuals. Operators can learn quickly but are still reminded of safety protocols. Such measures are crucial.

Moreover, the automatic shut-off mechanisms enhance safety. If a drill encounters abnormal resistance, it ceases operation. This feature helps prevent injuries caused by sudden equipment failure. Workers can work with increased peace of mind. However, it is not a replacement for proper training and vigilance on-site. Although jack leg drills represent progress, a culture of safety must be maintained. Regular training sessions can reinforce safety habits.

Versatility of Jack Leg Rock Drills in Different Rock Conditions

Jack leg rock drills are popular for their adaptability to various rock formations. These drills can effectively penetrate through different rock types, from soft limestone to hard granite. In fact, a study by the International Society for Rock Mechanics found that jack leg drills maintain a high penetration rate in both soft and hard rocks, achieving an average of 20% higher efficiency than conventional methods.

The versatility of jack leg rock drills extends beyond just rock types. They can be adjusted to drill at different angles, making them suitable for diverse project requirements. This flexibility allows operators to navigate complicated drilling patterns. Sometimes, drillers face challenges, like unexpected geological changes. However, the design of jack leg drills enables quick adjustments. This feature can save time and reduce costs when conditions become unpredictable.

Despite their advantages, jack leg drills may have limitations. For instance, the performance can decrease when used in excessively wet conditions. Additionally, operational training is crucial to maximize their benefits. A report by Mining Magazine highlighted that improper use can lower efficiency by up to 30%. Operators must be aware of these challenges to fully utilize the drill's capabilities. The ability to adapt and overcome obstacles is key to successful drilling projects.

Related Posts

-

Understanding the 2025 Top Jack Leg Rock Drill: Features and Applications

-

Top 10 Hand Held Rock Drills of 2025: Your Ultimate Buying Guide

-

Top 5 Mining Jack Hammers for Efficient Rock Breaking and Drilling

-

2025 Top Jack Leg Rock Drill Innovations: Features and Best Practices

-

Top Pneumatic Equipment Types You Should Know About?

-

Unveiling the Innovations: How Roof Bolting Machines Enhance Mine Safety and Efficiency