What is the Best 30m Depth Rock Drill for Your Projects?

In the construction and mining industries, choosing the right tool is vital. The "30m Depth Rock Drill" stands out as an essential piece of equipment for deep drilling projects. Industry expert Dr. James Carter emphasizes, “The right drill can make all the difference in project efficiency.”

Using a quality 30m Depth Rock Drill not only improves performance but also ensures safety. Many projects struggle because of outdated equipment or improper choices. A drill tailored for deep rock penetration can enhance productivity, yet many still rely on inadequate models.

It's crucial to evaluate the specific needs of your project. Whether for mining, geological exploration, or construction, the right choice matters. The complexity of the task often reveals itself in unexpected ways. Investing in a reliable 30m Depth Rock Drill can yield long-term benefits. Balancing quality and cost is essential, requiring careful consideration.

What to Consider When Choosing a 30m Depth Rock Drill for Projects

Choosing the right rock drill for a 30m depth project requires careful consideration of several factors. The first aspect is the type of drilling required. Different projects may have specific needs, whether for mineral exploration, construction, or geological surveys. Understanding the ground conditions is crucial. Hard rock formations demand robust equipment and specialized drill bits.

Another important aspect is the weight and portability of the drill. Some projects may be in remote locations. A lighter, more mobile drill can make a significant difference. Think about power sources, too. Hydraulic, electric, or pneumatic drills each have their pros and cons. It's also essential to consider maintenance needs. A drill that requires frequent servicing may lead to unexpected downtime.

Lastly, user experience is often overlooked. The comfort and ease of operation can greatly impact productivity. A drill that is hard to handle can slow down work. Don't forget to factor in training for the team as well. Proper training ensures safety and efficiency. Reflecting on these aspects will greatly enhance the success of your drilling project.

The Performance Comparison of 30m Depth Rock Drills

Key Features and Specifications of High-Performance Rock Drills

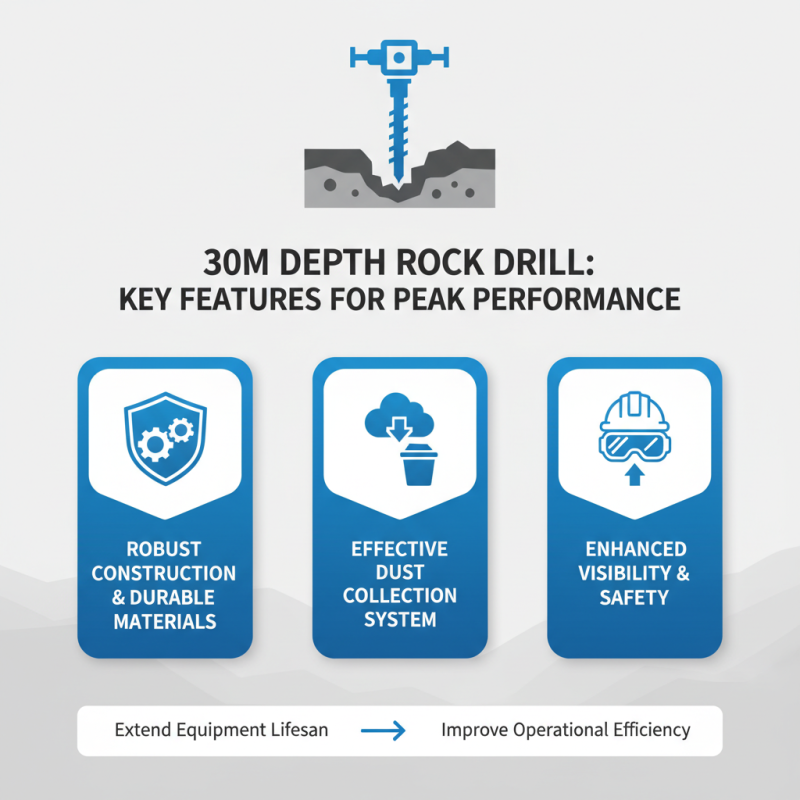

When selecting a 30m depth rock drill, consider key features that ensure peak performance. A high-quality drill should have robust construction to withstand harsh conditions. Durable materials extend the lifespan of the equipment. Look for models with effective dust collection systems. These systems enhance visibility and safety during operation.

Versatility matters. A drill that accommodates various bit sizes can make your projects more efficient. Compact designs increase maneuverability in tight spaces. Pay attention to weight as well—lighter drills reduce fatigue during extended use. Aim for options that combine power with user-friendly controls. This balance enhances precision.

**Tip:** Regular maintenance is crucial. Check and replace worn parts promptly. This prevents unexpected downtime and costly repairs.

Ensure the drill has an ergonomic design. Handles that facilitate a secure grip improve handling. This is particularly important in challenging environments. Integrated safety features help protect the operator from potential hazards.

**Tip:** Always refer to the manufacturer’s guidelines. Proper usage and care will ensure optimal performance and safety.

Top Brands and Models for 30m Depth Rock Drilling in the Industry

When considering rock drills for 30m depth projects, it's crucial to evaluate top brands and models that excel in efficiency and performance. Industry reports indicate that models with rotary percussive drilling capabilities often yield higher productivity. These drills can penetrate dense rock formations effectively. It's essential to review specifications carefully. Features such as weight, power output, and bit compatibility greatly influence performance.

Selecting a drill that balances power and portability is key. Lightweight models may offer easy handling in tight spaces. However, they often sacrifice drilling speed. Conversely, heavier options tend to be more powerful but could be challenging to transport. Always consider the specific requirements of your project before making a decision.

**Tip:** Regular maintenance is vital. Clean the drill after each use to prolong its lifespan. Ensure the drill is adequately lubricated, avoiding wear and tear. Performance can decline if proper care isn’t taken. Another aspect to think about is noise levels. Some drills can be quite loud, which might need an investment in protective gear. Pay attention to these details during your selection process.

What is the Best 30m Depth Rock Drill for Your Projects? - Top Brands and Models for 30m Depth Rock Drilling in the Industry

| Model | Maximum Depth (m) | Drilling Diameter (mm) | Weight (kg) | Power (kW) |

|---|---|---|---|---|

| Model A | 30 | 100 | 700 | 50 |

| Model B | 30 | 90 | 850 | 60 |

| Model C | 30 | 110 | 600 | 55 |

| Model D | 30 | 95 | 780 | 65 |

| Model E | 30 | 105 | 720 | 58 |

Safety Standards and Regulations for 30m Depth Rock Drilling

When it comes to 30m depth rock drilling, adhering to safety standards is paramount. According to the Occupational Safety and Health Administration (OSHA), approximately 78% of drilling accidents occur due to equipment failure or unsafe practices. Regular inspections and maintenance are crucial.

The International Organization for Standardization (ISO) emphasizes that drill operators should receive proper training. This training helps reduce the risk of human error. A recent industry report noted that companies implementing standard safety training saw a 40% decrease in incidents. These figures demonstrate the importance of safety adherence.

Protective gear is essential in rock drilling operations. Workers must wear helmets, goggles, and non-slip footwear. The right equipment can save lives. Yet, many sites still lack proper safety measures. According to a survey, 32% of workers reported insufficient protective equipment at their sites. It’s a glaring issue in the industry. Safety must always be a priority.

Cost Analysis: Budgeting for a 30m Depth Rock Drill and Maintenance Costs

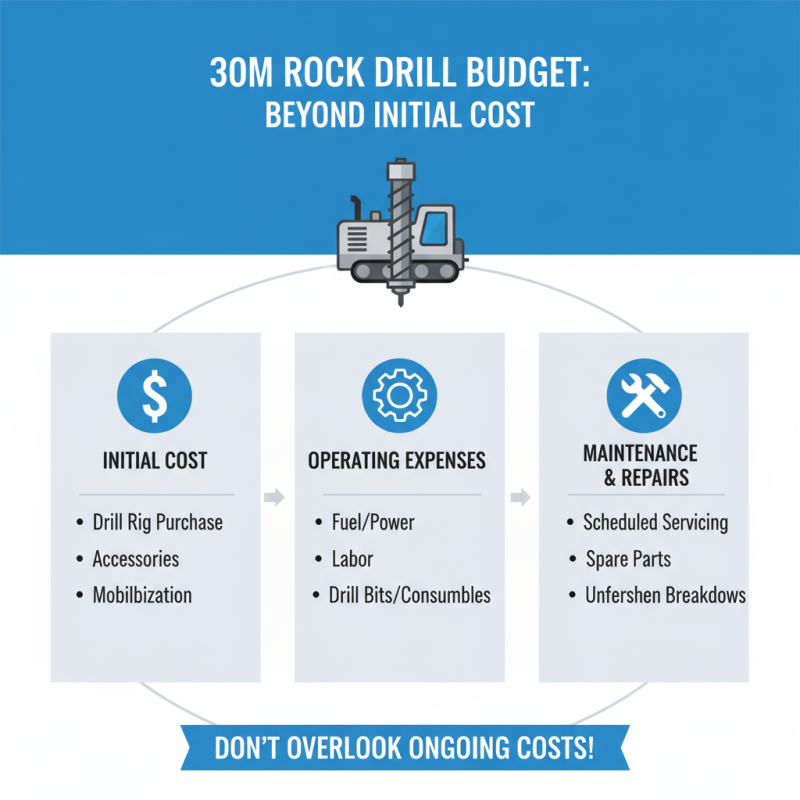

When planning for a 30m depth rock drill, budgeting is crucial. The initial cost is only the beginning. You need to factor in operating expenses, maintenance, and possible repairs. Each of these areas can impact your overall project budget significantly. Often, buyers overlook ongoing costs.

Maintenance costs can accumulate quickly. Schedule regular check-ups to avoid hefty repair bills later. This small investment can lead to long-term savings. It is wise to set aside at least 10-15% of your initial budget for maintenance. Ignoring this can result in unexpected downtime.

Tip: Keep an eye on power consumption. Drills vary in energy efficiency. Higher efficiency means lower operational costs. Analyze performance data regularly. Awareness can help you adjust your usage effectively.

Another tip: Train your team thoroughly. A well-trained operator can prolong the lifespan of the drill. Improper use can lead to frequent repairs. Sometimes, simple mistakes add unnecessary expenses. Reflect on training methods to improve efficiency.

Related Posts

-

Top 10 Hand Held Rock Drills of 2025: Your Ultimate Buying Guide

-

2025 Top Jack Leg Rock Drill Innovations: Features and Best Practices

-

Exploring the Industry Trends of Jack Hammer Manual at the 2025 China Import and Export Fair

-

Why Do Drilling Rig Prices Vary? Key Factors Affecting Costs Explained

-

Exploring the Benefits of Portable Ventilators: Your Guide to Respiratory Relief Anytime, Anywhere

-

Innovative Safety Mining Lamp Solutions Enhancing Worker Protection in Harsh Environments