How to Choose the Best 30m Depth Rock Drill for Your Project Needs

When embarking on a geological project that requires drilling into solid rock, selecting the right equipment is crucial for success. The 30m Depth Rock Drill stands out as a versatile option for many applications, offering the ability to reach significant depths with efficiency. With a broad range of models available, choosing the appropriate drill depends on several project-specific factors, including the type of rock being drilled, the environmental conditions, and the overall objectives of the drilling operation.

Understanding the capabilities and features of a 30m Depth Rock Drill is essential for making an informed decision. Key considerations include the drill's power, speed, and penetration rate, as these elements directly influence productivity and efficiency. Additionally, assessing the drill's portability and ease of use can enhance operational workflow, ensuring that it meets the specific demands of your project.

By taking the time to evaluate these factors meticulously, project managers can identify the best 30m Depth Rock Drill that aligns with their requirements. This thoughtful approach not only maximizes the potential for successful drilling results but also contributes to safe and effective project execution. Whether you are a seasoned professional or new to the drilling industry, this guide aims to equip you with the insights needed to make the best choice for your drilling needs.

Understanding Your Project Requirements for Rock Drilling

When selecting a rock drill, particularly one capable of reaching depths of 30 meters, it's essential to start by understanding your specific project requirements. Consider the geological conditions of the site. Different types of rock formations—such as granite, limestone, or sedimentary rock—can significantly influence the choice of drill. For instance, harder rock types may necessitate a drill with higher torque and robust bit designs to ensure efficiency and reduce wear.

Additionally, assess the scale and purpose of your project. Are you drilling for the installation of foundation pilings, geothermal systems, or mining purposes? Each application has distinct demands that will impact the choice of a rock drill. Moreover, evaluate factors such as the desired penetration rate, the necessary drilling angle, and the volume of drilling expected. Having a clear understanding of these elements will guide you toward selecting a rock drill that not only meets the depth requirements but also aligns with your operational goals and budget constraints.

Key Features to Consider in a 30m Depth Rock Drill

When selecting a 30m depth rock drill, it is essential to focus on key features that enhance performance and efficiency. One of the most critical factors is the drill's power output, typically measured in horsepower (HP). According to industry reports, drills with a power rating above 80 HP are recommended for effectively penetrating dense rock formations, ensuring optimal productivity. Additionally, torque is another important parameter, as higher torque ratings enable the drill to tackle challenging geological conditions without stalling.

Another crucial feature to consider is the drill's stabilization system. A well-designed stabilization system minimizes vibrations, leading to more accurate drilling and reducing wear and tear on both the drill and surrounding infrastructure. Research suggests that drills with advanced stabilization technologies can improve drilling accuracy by up to 25%, a significant advantage for projects requiring precision. Additionally, weight distribution plays a role in the overall handling of the drill, impacting maneuverability in tight spaces or uneven terrains.

Finally, assess the drill's maintenance requirements and ease of use. Drills that offer user-friendly control systems and easy access to maintenance points can significantly reduce downtime and increase overall operational efficiency. A report by the International Society of Rock Mechanics highlights that minimizing maintenance-related disruptions can improve project timelines by as much as 30%. By evaluating these key features, you can ensure that your selection aligns with your project needs and enhances productivity in the challenging field of rock drilling.

Key Features Comparison of 30m Depth Rock Drills

Evaluating the Performance and Durability of Rock Drills

When evaluating the performance and durability of rock drills, several key factors

come into play that can significantly influence your project's efficiency and

cost-effectiveness. A crucial aspect to consider is the drill's penetration rate,

which typically ranges from 0.8 to 1.5 meters per minute

for high-quality 30m depth rock drills. This metric directly impacts productivity,

especially in time-sensitive projects. The performance of the drill can also be affected

by the type of rock being drilled; for instance, quartzite

formations may cause a 30% decrease

in penetration compared to softer sedimentary rocks.

In terms of durability, materials used in the construction of the drill play an

essential role. High-grade steel alloys and advanced composite materials

can enhance the drill’s resistance to wear and tear, with some reports indicating that

drills made from these materials can last up to 30% longer

under continuous use. Additionally, the design of the drill bits must account for heat

dissipation and stress distribution, as poorly designed bits can lead to premature wear,

increasing downtime and maintenance costs. A comprehensive analysis, such as that from the

International Society for Rock Mechanics,

emphasizes that maintaining optimal operating conditions and regular maintenance schedules can further

extend the life cycle of rock drills, ensuring that they remain a valuable asset

throughout the duration of your project.

Comparing Different Brands and Models of Rock Drills

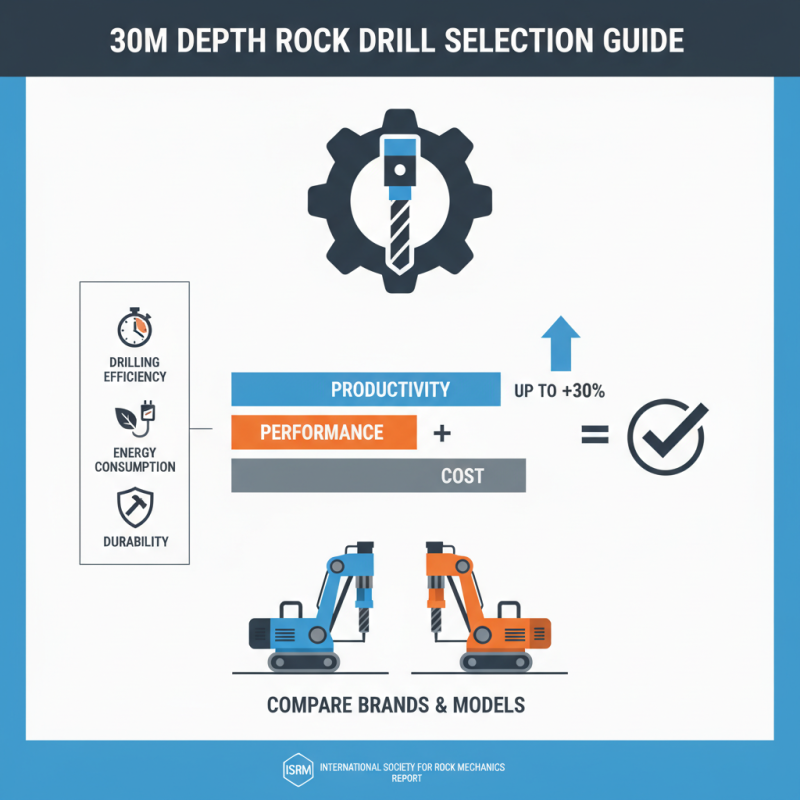

When selecting a 30m depth rock drill for your project, it’s crucial to compare the various brands and models available in the market to identify which best suits your specific requirements. According to a report by the International Society for Rock Mechanics, factors such as drilling efficiency, energy consumption, and durability are pivotal when assessing different rock drill options. A good rock drill should provide a balance between performance and cost, with reports indicating that productivity can increase by up to 30% with the right equipment.

In terms of performance metrics, some models are equipped with advanced features like intelligent monitoring systems that optimize drilling parameters in real time. Research by the Construction Industry Institute shows that these enhancements lead to more precise drilling, reducing the incidence of rock fragmentation, which in turn minimizes environmental disturbances. Evaluating performance specifications, such as the rate of penetration and torque outputs, is critical, as these directly impact project timelines and costs. Ultimately, thorough comparisons based on reliable industry data will empower you to make an informed decision that aligns with your operational goals.

Budgeting and Cost Considerations for Your Rock Drill Purchase

When budgeting for a 30m depth rock drill, it's essential to consider the total cost of ownership, which goes beyond the initial purchase price. Starting with the cost of the drill itself,

you should factor in additional expenses such as spare parts, maintenance, and accessories. Rock drills require

regular upkeep to ensure optimal performance and longevity. Allocating a budget for these ongoing costs can prevent unexpected financial strain down the line.

Furthermore, it's vital to assess the project's requirements and the drill's specifications. High-quality drills may come with a higher price tag, but investing in a reliable model can lead to increased productivity and

reduced downtime. Additionally, consider the operational costs, including energy consumption and labor needs. A more

efficient drill may save money in the long run, justifying a higher initial investment. By thoroughly evaluating these factors, you can make an informed decision that aligns with both your financial constraints and project demands.

Related Posts

-

How to Enhance Indoor Air Quality with Advanced Ventilation Machines for Healthier Living Spaces

-

Maximizing Efficiency: Why Integral Drill Rods Are Essential for Modern Drilling Techniques

-

What is Pneumatic Equipment? Understanding Types and Applications Explained

-

Unlocking the Darkness: Why Mining LED Headlamps Are Essential for Modern Miners

-

2025 Top Jack Leg Rock Drill Innovations: Features and Best Practices

-

The Ultimate Guide to Choosing the Best Electric Rock Drill for Your Projects