2026 How to Choose the Right Sewage Slurry Pump for Your Needs?

Selecting the right sewage slurry pump can feel overwhelming. The market offers various options. Each pump comes with distinct features and specifications. Understanding these can shape your decision.

Sewage slurry pumps are critical in waste management. They handle challenging materials, including slurries and thick liquids. Choosing the wrong pump could lead to inefficiency and higher costs. Consider factors like pump size, power, and material. These elements play a vital role in performance.

Reflecting on past experiences is essential. Many have faced issues due to hasty choices. A detailed requirement analysis can expose your needs better. In the end, the right sewage slurry pump can significantly boost operations and reduce headaches.

Understanding Sewage Slurry Pumps: Types and Applications

Sewage slurry pumps are essential in various industries. Understanding the types and their applications helps in selecting the right one. These pumps are designed to handle mixtures of water and solids. They often deal with wastewater, slurries, and sludge.

There are several types of sewage slurry pumps available. Some are submersible, while others are centrifugal. Each type has its advantages and specific applications. Submersible pumps are usually used for deep-water applications. They can operate underwater, reducing installation space. Centrifugal pumps are more versatile and often found in industrial settings.

When choosing a pump, consider the specific requirements of your project. Think about the flow rate, head height, and the nature of the material. Not every pump will fit every job. Sometimes, you may have to compromise based on available options. It's essential to gather accurate information on these factors for an informed decision. Seeking advice from experienced professionals can also be beneficial.

Factors to Consider When Choosing a Sewage Slurry Pump

Choosing the right sewage slurry pump requires careful consideration of several factors. The type of material that needs to be pumped is crucial. For example, abrasive materials may require a stronger pump. According to recent industry reports, nearly 30% of pump failures are due to improper material selection. Understanding the types of solids in the slurry is essential.

Another key factor is the pump's capacity. Sewage pumps vary widely in their volume handling. Some can manage up to 1,000 gallons per minute, while others are suitable for smaller operations. This variation can significantly impact efficiency and operational costs. Additionally, most users underestimate the importance of the pump’s head, which is vital for determining how high the fluid needs to be lifted.

Also, consider the energy consumption of the pump. A more energy-efficient model can save substantial costs in the long run. Data suggests that replacing an old pump with a modern, efficient one can reduce energy consumption by up to 50%. Yet, many systems continue using outdated technology, reflecting a gap in optimal equipment usage. Each choice affects not only performance but also long-term maintenance and operational costs.

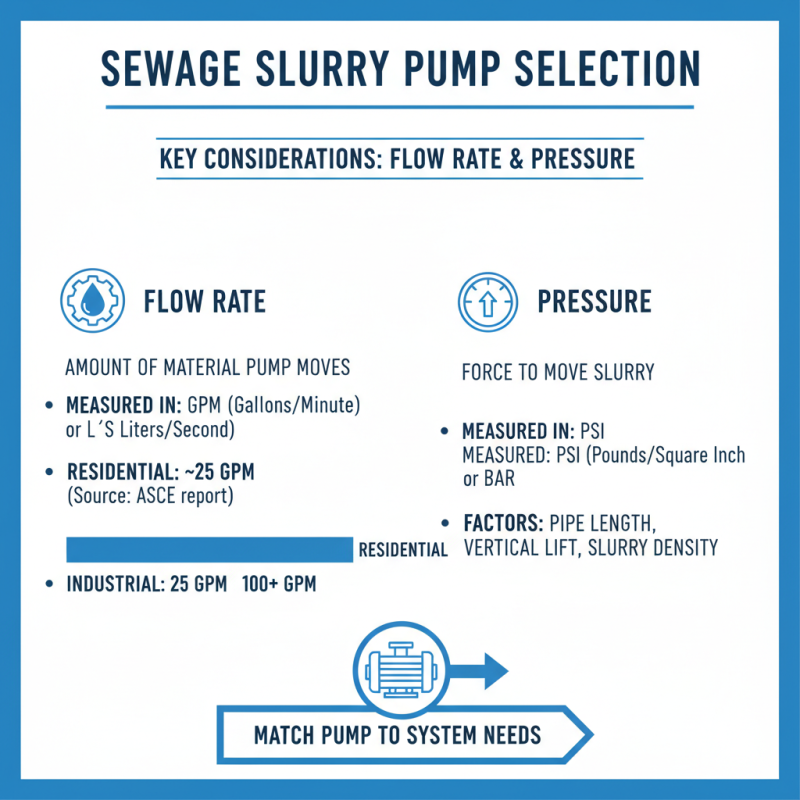

Assessing Flow Rate and Pressure Requirements for Your Pump

When selecting a sewage slurry pump, assessing flow rate and pressure requirements is crucial. Flow rate, measured in gallons per minute (GPM) or liters per second, determines how much material the pump can move. A report by the American Society of Civil Engineers indicates that the average flow rate for residential sewage systems is around 25 GPM. However, industrial applications may require much higher rates, often exceeding 100 GPM.

Pressure is equally important. The pump must generate enough pressure to overcome the system's resistance. According to the Hydraulic Institute, a pump should deliver at least 10 PSI to effectively transport slurry across moderate distances. Underestimating pressure needs can lead to inefficient operation and costly failures. Selecting a pump with adjustable pressure settings could offer flexibility for varying application needs.

It’s essential to consider both aspects carefully. Miscalculating either flow rate or pressure can lead to severe operational issues. Inadequate flow may cause clogging, while too much pressure could damage the system. Therefore, assessing your specific needs with accurate calculations is vital. Investing time in this evaluation pays off in reliable performance.

Material Compatibility: Selecting the Right Pump for Your Slurry

Choosing the right sewage slurry pump begins with understanding material compatibility. The pump's material must withstand the chemical nature of the slurry. Different slurries have various pH levels, corrosiveness, and abrasive properties. For example, mixtures with high acidity can deteriorate certain materials quickly.

When assessing compatibility, consider the solids content in your slurry. High solid content can wear down the pump. This requires durable materials like stainless steel or specialized alloys. It's crucial to match the pump material to the specific characteristics of the slurry.

**Tips:** Conduct a thorough analysis of your slurry's composition. Engage experts if necessary. A small mistake in material selection can lead to costly repairs. Always seek feedback from operators who have experience with similar materials. Their insights can help you avoid potential pitfalls.

Additionally, consider the operating environment. Factors like temperature, pressure, and exposure to chemicals will impact pump performance. Evaluate all these conditions to ensure the longevity and efficiency of your pump. A well-chosen pump can save time and money in the long run.

2026 How to Choose the Right Sewage Slurry Pump for Your Needs?

The following chart illustrates the material compatibility of different sewage slurry pumps based on their ability to handle various types of slurry. The data represents the percentage effectiveness of each pump material when dealing with different slurry compositions.

Maintenance and Lifespan: Ensuring Optimal Pump Performance

When it comes to sewage slurry pumps, maintenance plays a crucial role. Regular maintenance ensures your pump operates efficiently. Neglect can lead to decreased performance and a shorter lifespan. Checking components like seals, bearings, and impellers is vital. Small issues can escalate into costly repairs.

Tips: Schedule routine inspections. This helps catch problems early. Keep a log of maintenance activities. Note any unusual noises or vibrations. These can be early indicators of wear.

Inspecting and cleaning filters regularly is essential. Clogged filters can strain the pump, causing overheating. Replacement parts should match specifications closely. Mismatched components can affect efficiency. Be cautious about DIY repairs. Sometimes, professional help is necessary.

Tips: Familiarize yourself with your pump's manual. An informed owner can better address issues as they arise. Understand that all pumps have a limited lifespan. Planning for replacement can save time and resources.

Related Posts

-

Top 10 Best Vertical Slurry Pumps for Efficient Slurry Management

-

Top Mining Slurry Pumps of 2025: Features, Benefits, and Buying Guide

-

Exploring the Benefits of Portable Ventilators: Your Guide to Respiratory Relief Anytime, Anywhere

-

Why Invest in Mining LED Headlamps for Enhanced Safety and Efficiency?

-

Maximizing Efficiency: Why Integral Drill Rods Are Essential for Modern Drilling Techniques

-

10 Essential Tips for Optimizing Your 30m Depth Rock Drill Performance