How to Choose the Best Hand Held Rock Drill for Your Projects?

Choosing the right Hand Held Rock Drill can significantly impact your project’s success. According to a recent industry report, over 70% of construction professionals emphasize the importance of high-quality drills. The right tool enhances efficiency and reduces project timelines.

In various sectors, including mining and construction, Hand Held Rock Drills are essential for applications like concrete and rock drilling. Research indicates that improper tool selection can lead to a 30% increase in operational costs. Features like weight, power, and durability are critical factors to consider.

However, many users often overlook these details. Selecting a drill that doesn’t fit your project's needs can result in frustration and inefficiencies. Consider how these tools perform under different conditions. A well-informed decision can lead to better outcomes, while a hasty choice may require re-evaluation later on.

Understanding the Different Types of Hand Held Rock Drills

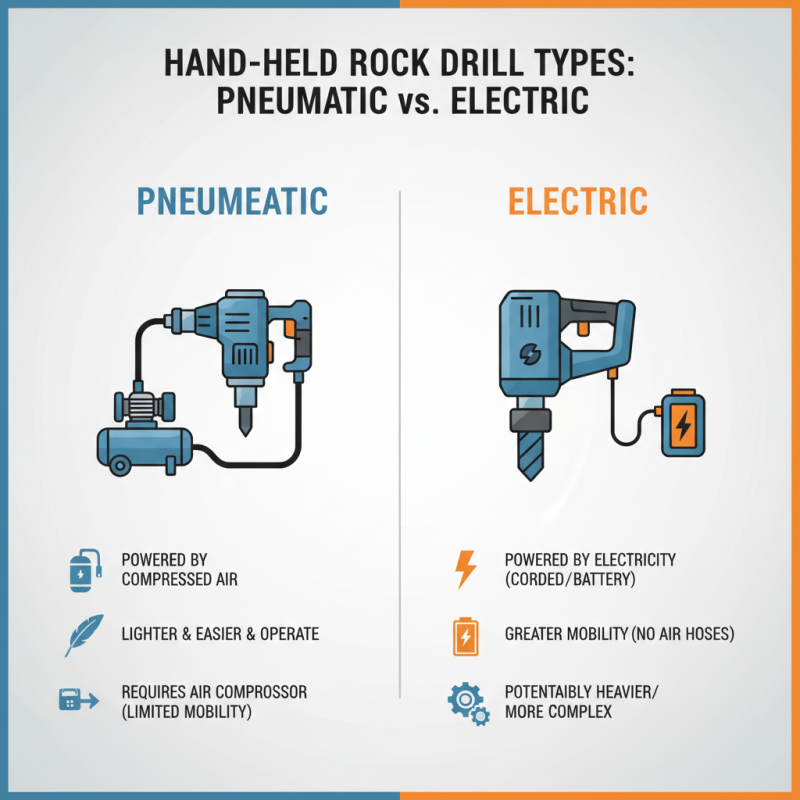

When choosing a hand-held rock drill, it's essential to understand the different types available. Generally, these drills fall into two main categories: pneumatic and electric. Pneumatic drills are powered by compressed air. They are often lighter and easier to operate. However, they may require an air compressor, which can limit mobility on a job site.

Electric hand-held rock drills offer their own advantages. They are usually more powerful and ideal for prolonged use. However, they need a power source, which can be inconvenient in remote locations. Another option includes gasoline-powered models. These can be highly portable, but they require regular maintenance and may produce fumes.

It’s vital to consider your project specifics. Think about rock hardness and depth requirements. Also, evaluate the weight and ergonomics of the drill. A tool that feels comfortable in your hands will help reduce fatigue during long hours of work. Remember, each type has unique features and drawbacks. Assess what you need to prioritize to ensure you choose the best one for your tasks.

Key Features to Look for in a Hand Held Rock Drill

When choosing a hand-held rock drill, look for key features that provide efficiency and comfort. The power source matters. Electric drills are quieter, while gas-powered ones offer more mobility. Consider the weight. A heavier tool can be more tiring during prolonged use. Balance and ergonomics play a crucial role in reducing fatigue.

Another essential feature is the drill bit type. Sharp and durable bits enhance performance. Check the drilling capacity too. Some drills handle harder materials better than others. Don't forget about vibration control. Tools with good damping systems minimize hand strain, making it easier to work longer.

Tips: Always prioritize safety. Wear protective gear like gloves and goggles. Test the drill before committing to extensive use. Experiment with different bits to find your best fit. Adjust your grip periodically to avoid discomfort. Remember, comfort directly affects productivity.

Assessing Power and Performance for Your Specific Projects

Choosing the right hand-held rock drill is crucial for the success of your projects. Assessing power and performance is vital. Different projects demand varying levels of energy and efficiency. For instance, lightweight drills are effective for softer rock, while heavier models excel in more challenging conditions. According to industry reports, a drill's power is often measured in horsepower (HP). A higher HP generally translates to better performance in tough materials.

When evaluating a drill, consider its impact rate. This indicates the number of blows per minute. A drill with a higher impact rate will penetrate rock faster, saving you time. For instance, drills offering 1,500 to 3,000 impacts per minute are typically more efficient in hard rock applications. However, always check if the drill’s weight is manageable for extended use. Heavy models can be tiring.

Tips: Ensure your drill comes with adjustable power settings. This flexibility allows you to match the power output to the project's demands. Pay attention to ergonomics. A comfortable grip can prevent strain during long hours of work. Lastly, reading user reviews can provide insight into the drill's real-world performance and reliability.

Evaluating Durability and Maintenance Needs of Rock Drills

When choosing a hand-held rock drill, durability is a significant factor. Reports indicate that over 40% of drills fail within the first year due to inadequate materials or craftsmanship. Many users often overlook maintenance needs, which can lead to early breakdowns. Proper care can extend the lifespan of these tools significantly.

Evaluating the materials used in construction is crucial. High-quality steel and reinforced components can resist wear and tear. Some studies show that drills made from durable alloys can operate efficiently for up to 3,000 hours with minimal issues. Regular maintenance, such as lubricating moving parts, is vital. Neglect can result in costly repairs and downtime.

It's also important to consider how easily a drill can be repaired. Some designs are notoriously challenging to service. This can lead to increased costs in the long term. User feedback reveals that convenience in maintenance should not be underestimated. Inadequate access to critical components can frustrate operators, affecting productivity. Balancing durability and maintenance needs will ensure better performance and longer-lasting equipment.

How to Choose the Best Hand Held Rock Drill for Your Projects? - Evaluating Durability and Maintenance Needs of Rock Drills

| Model | Weight (lbs) | Drilling Capacity (inches) | Durability Rating (1-10) | Maintenance Frequency (months) |

|---|---|---|---|---|

| Model A | 12 | 1.5 | 8 | 6 |

| Model B | 15 | 2.0 | 9 | 12 |

| Model C | 10 | 1.25 | 7 | 9 |

| Model D | 14 | 2.5 | 10 | 8 |

Comparing Prices and Brands for Best Value in Hand Held Drills

When selecting a hand-held rock drill, price and brand play significant roles. The market offers a wide range in pricing, from budget options around $150 to premium models exceeding $1,000. According to a recent industry report, the average cost of a reliable hand-held rock drill is about $400. Users often seek a balance between affordability and quality. Brand reputation can influence this decision, but it’s not the only factor to consider.

Many consumers gravitate toward popular brands due to perception. However, a noteworthy finding from the same report is that lesser-known brands can provide comparable quality at a lower price. The report indicates that 45% of users reported satisfaction with budget drills that outperformed their pricier counterparts in specific use cases. Each project has unique demands, making it essential to closely evaluate specifications and features.

In the realm of comparisons, the choice isn't always straightforward. Users sometimes overlook the significance of warranty and support service. A cheaper drill might lack adequate customer service, leading to frustration. Reviews can be useful, yet they often present an idealized perspective. Real-world performance may differ. As you choose your drill, consider both monetary value and long-term reliability.

Comparison of Hand Held Rock Drill Features

Related Posts

-

Top 10 Hand Held Rock Drills of 2025: Your Ultimate Buying Guide

-

Top Hand Held Rock Drill Models for Efficient Mining Operations?

-

2025 Top Jack Leg Rock Drill Innovations: Features and Best Practices

-

Understanding the 2025 Top Jack Leg Rock Drill: Features and Applications

-

Top 10 Benefits of Using a 30m Depth Rock Drill for Your Projects

-

Top 10 Benefits of Using a Jack Leg Rock Drill?