Why Hydraulic Drill Rigs Are Essential for Modern Construction Projects?

In the fast-evolving world of construction, Hydraulic Drill Rigs have emerged as indispensable tools. Recent reports from the Construction Industry Institute reveal that these machines enhance drilling efficiency by up to 30%. This efficiency is critical as construction projects become more complex and time-sensitive. Hydraulic Drill Rigs offer unparalleled precision and power, enabling projects to meet demanding deadlines.

Expert in the field, Dr. Emily Grant, emphasizes their importance: "Hydraulic Drill Rigs are reshaping how we approach modern construction." Her insights underscore that as cities expand, these rigs facilitate the installation of essential infrastructure. They are vital for laying foundations and utility lines, especially in urban settings where space is limited.

However, reliance on Hydraulic Drill Rigs raises questions about sustainability. The use of hydraulic fluids can lead to environmental concerns if not managed properly. Acknowledging these challenges is necessary as we embrace technology in construction. Balancing efficiency and environmental responsibility must guide future innovations in Hydraulic Drill Rigs.

Importance of Hydraulic Drill Rigs in Contemporary Construction

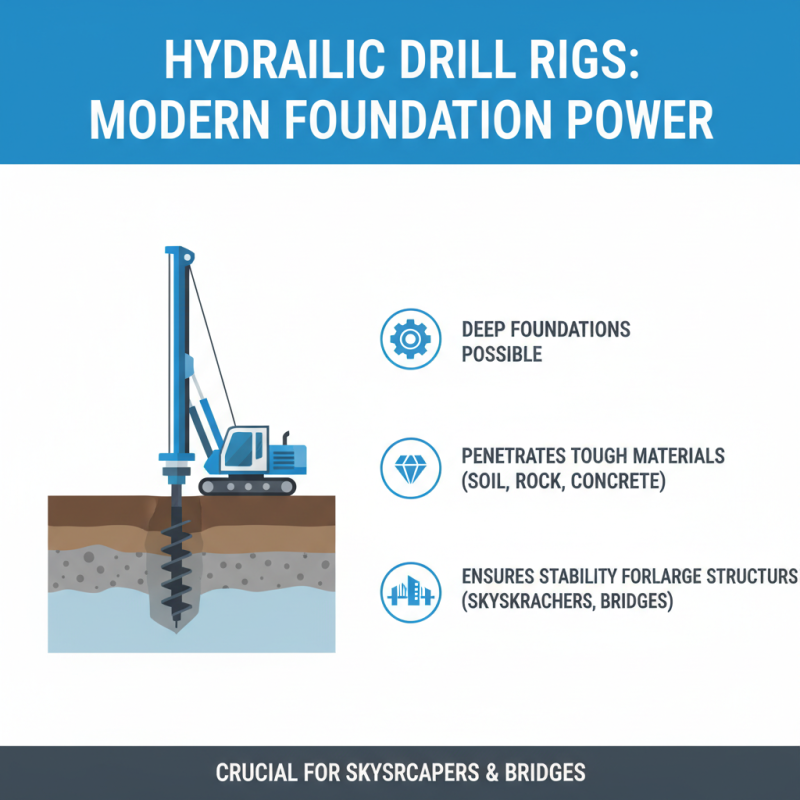

Hydraulic drill rigs play a vital role in modern construction. These machines make deep foundations possible. Their ability to penetrate tough materials is unmatched. They handle soil, rock, and concrete with ease. This ensures stability for large structures. For skyscrapers or bridges, solid foundations are crucial.

One notable feature is their precision. Hydraulic drills can reach specific depths. They create holes that suit various construction needs. This helps save time and reduce costs. Yet, it's important to recognize some limitations. Maintenance is essential to ensure optimal performance. Failing to maintain can lead to inefficiencies. Some operators may overlook this, leading to delays.

The noise and vibrations caused by hydraulic drills can also be a concern. They affect nearby residents and wildlife. It’s essential for construction teams to communicate with the community in this regard. Overall, balancing efficiency with community needs remains a challenge. These machines are essential, but their impact must be managed carefully.

Key Features of Hydraulic Drill Rigs That Enhance Efficiency

Hydraulic drill rigs are vital in modern construction. Their design offers several key features that enhance efficiency. One noticeable advantage is their ability to operate in tough terrains. With powerful hydraulic systems, they penetrate hard soils easily. This capability saves time and reduces labor costs.

Speed is another major benefit. Hydraulic drills can rapidly drill deep holes. This efficiency speeds up overall project timelines. Additionally, these rigs often feature automated controls. Operators can fine-tune the drilling process, enhancing precision. This reduces the chances of errors, but occasionally, adjustments may be needed during operations.

Moreover, hydraulic drill rigs have a smaller footprint. This characteristic is particularly useful in urban settings. Less space minimizes disruption to surrounding areas. However, navigating tight spaces can be challenging. Operators must carefully plan their approach. They may still encounter obstacles, requiring a quick rethink of their strategy.

Why Hydraulic Drill Rigs Are Essential for Modern Construction Projects?

| Feature | Description | Benefit |

|---|---|---|

| High Torque | Provides strong rotational force for efficient drilling. | Increases drilling speed and reduces operational time. |

| Versatility | Can be used for various soil types and construction needs. | Adaptable to different project requirements. |

| Reduced Noise | Quieter operation compared to traditional drilling methods. | Minimizes noise pollution at construction sites. |

| Automated Controls | Features advanced control systems for precise operations. | Enhances accuracy and reduces the need for manual adjustments. |

| Increased Stability | Stable design minimizes shifting during operation. | Improves safety and drilling consistency. |

Applications of Hydraulic Drill Rigs Across Various Construction Projects

Hydraulic drill rigs play a crucial role in modern construction. These machines are vital for various applications, such as foundation digging, soil sampling, and tunneling. According to recent industry reports, the global market for hydraulic drilling equipment is expected to grow by over 4% annually through 2025. This growth reflects their importance in meeting project deadlines and ensuring safety standards.

In urban construction projects, hydraulic drill rigs enable precise drilling for foundations. They are also essential in mining operations, where accuracy enhances resource extraction efficiency. Advanced hydraulic systems allow for better control, particularly in congested areas. This technology reduces noise and vibration, making it safer for nearby structures and residents.

**Tip:** Regular maintenance of hydraulic systems ensures optimal performance. Check seals and fluid levels frequently. Also, keep operators well-trained to prevent costly errors. Small mistakes can lead to significant delays, impacting project timelines and budgets.

Hydraulic drill rigs are also used in utility installations. Tasks like water and gas line placements require reliable technology. However, site conditions can complicate operations. Unexpected rock formations or unstable soil may cause setbacks. Engineers must prepare for these challenges, ensuring projects stay on track.

Advantages of Using Hydraulic Drill Rigs Over Traditional Methods

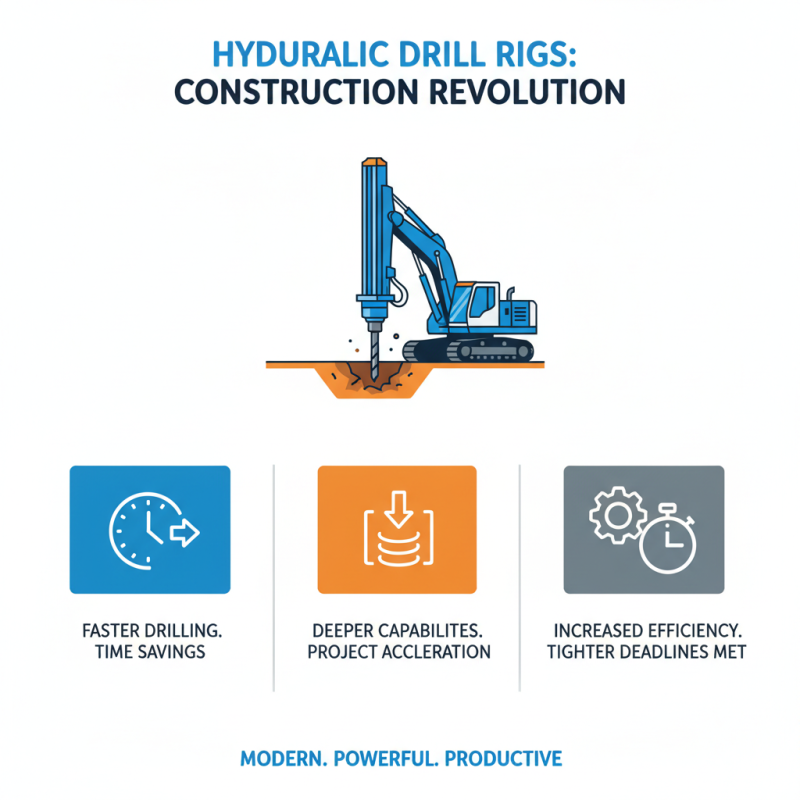

Hydraulic drill rigs have transformed modern construction projects. They provide several advantages over traditional digging methods. One key benefit is efficiency. Hydraulic rigs can drill quicker and deeper than standard equipment. This leads to significant time savings on projects. In a world where deadlines are tight, every second counts.

Additionally, these rigs are often more precise. They can reach specific depths and angles with accuracy. This reduces the chances of costly mistakes. Traditional drilling methods may not offer the same level of control. Consequently, projects can face delays and budget overruns due to unforeseen errors.

Despite these benefits, there are challenges. Hydraulic rigs can be expensive to purchase and maintain. Not every construction team has access to this technology. Training is also necessary. Workers must learn how to operate these machines safely. Yet, as construction evolves, the advantages generally outweigh the drawbacks. Employing hydraulic drill rigs is becoming increasingly essential in today’s competitive market.

Future Trends in Hydraulic Drilling Technology for Construction Industry

The construction industry is undergoing significant transformations with advances in

hydraulic drilling technology. This evolution is

driven by the need for efficiency and

precision. Hydraulic drill rigs allow for rapid site preparation and minimal disruption. They can penetrate

various soil types, making them versatile for diverse

projects. These rigs often reduce manual labor, which can pose safety risks on site. However, reliance on

technology raises questions about job displacement.

Future trends indicate a shift towards automation.

Enhanced robotics and AI are being integrated into hydraulic drills. This could improve accuracy and speed even further. Yet, adopting

these technologies requires careful consideration. Training workers to manage sophisticated machinery is

crucial. There is a risk of skills gaps emerging in the

workforce. Additionally, maintenance and operational costs could increase as technology advances.

Another trend is the emphasis on sustainability.

New hydraulic drilling methods aim to minimize environmental impact. Innovations in fuel efficiency and

reduced noise levels are being sought after. However, not all new technologies are foolproof. There are

challenges to overcome, such as ensuring reliability under varying conditions. Construction firms must

remain adaptable as they explore these trends. Balancing innovation with practical applications is essential

for future success.

Related Posts

-

Exploring Innovations in Hydraulic Drill Rigs at the Upcoming 2025 China Import and Export Fair

-

10 Essential Tips for Optimizing Your 30m Depth Rock Drill Performance

-

Understanding the 2025 Top Jack Leg Rock Drill: Features and Applications

-

Unlocking the Darkness: Why Mining LED Headlamps Are Essential for Modern Miners

-

How to Choose the Best 30m Depth Rock Drill for Your Project Needs

-

How to Choose the Best Led Mining Cap Lamp for Optimal Safety and Efficiency in Underground Operations