Best Integral Drill Rod Features and Benefits Explained?

In the realm of drilling, the Integral Drill Rod stands out as a vital tool. It uniquely combines strength and functionality, making it essential for various applications. This rod is designed to withstand intense conditions, ensuring efficient drilling in tough environments.

When considering the features of an Integral Drill Rod, one must appreciate its durability and versatility. The rod's seamless construction contributes to its robustness. It minimizes the risk of failure, an essential factor for many projects. However, not all Integral Drill Rods are created equal. Quality can vary among manufacturers, leading to performance inconsistencies.

Investing in the right Integral Drill Rod is crucial. The benefits can be significant, impacting productivity and cost-effectiveness. Yet, one must carefully evaluate options. Overall, this tool is invaluable, though it requires thoughtful consideration before procurement. Understanding its features and limitations can ultimately lead to better drilling outcomes.

Best Integral Drill Rod Features: Material Composition and Durability

Integral drill rods are vital in drilling operations. The materials used in their production greatly affect performance and durability. Commonly, these rods are made from high-strength alloy steel. This steel composition enhances resistance to wear and fatigue, leading to longer service life. According to industry reports, rods made with advanced metallurgical processes can endure up to 30% more stress compared to standard options.

Durability is another crucial factor. The heat treatment processes applied to integral drill rods contribute significantly to their longevity. These processes create a tougher exterior without compromising flexibility. Data indicates that properly treated rods can last 25% longer than untreated versions in rigorous environments. However, manufacturers often overlook the importance of proper maintenance. Not addressing wear and tear can lead to premature failure, which is a common issue faced in the field.

It is also essential to consider environmental factors. Corrosion-resistant coatings can enhance the lifespan, but environmental conditions like humidity or salinity can still pose risks. Operators must remain vigilant and regularly inspect their equipment. The balance between material quality and maintenance practices is vital for optimal efficiency and longevity of drill rods.

Best Integral Drill Rod Features and Benefits

This chart illustrates the key features of integral drill rods, showcasing material composition, durability, weight, and flexibility. These dimensions reflect the essential qualities that make integral drill rods effective and durable in various drilling conditions.

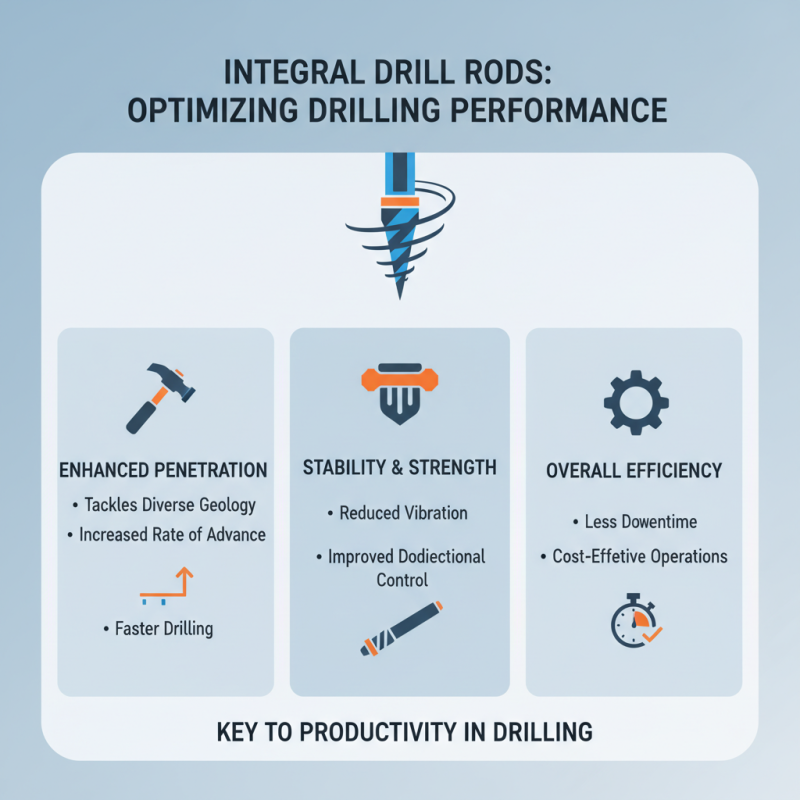

Performance Benefits: Enhanced Penetration Rate in Various Geological Conditions

Integral drill rods are essential in the drilling industry, especially for optimizing performance. Enhanced penetration rates are crucial for tackling various geological conditions. These rods are designed to improve drilling efficiency significantly. They achieve this by providing better stability and strength during operations.

When drilling through challenging terrains like rock, clay, or hard soil, the right drill rod can make a difference. A well-constructed integral drill rod can offer superior torque, allowing for smoother drilling. However, not all drilling applications are the same. Some users might find that their rods struggle in mixed formations. This inconsistency can lead to unexpected downtime, affecting project timelines.

Another point to consider is the weight of the drill rod. Heavier rods can provide better penetration but may slow down operations. In addition, users must balance durability with flexibility. Finding that perfect match often requires trial and error. It's essential to test your equipment under varying conditions to see how it handles different challenges. Adjustments may be necessary to enhance performance in specific environments.

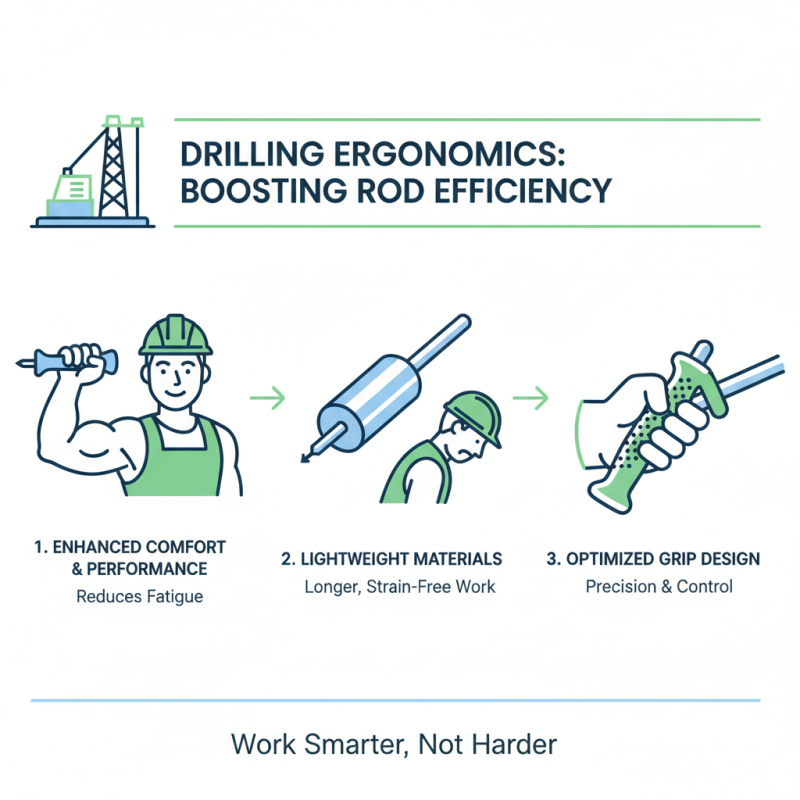

Design Innovations: The Role of Ergonomics in Drill Rod Efficiency

In the world of drilling, ergonomics plays a crucial role in rod efficiency. A well-designed drill rod not only enhances performance but also improves user comfort. This is essential for long working hours. Lightweight materials can reduce fatigue, allowing operators to work longer without strain. Proper grip designs can enhance control, making it easier for users to perform precise actions.

Innovations in design often focus on user experience. For instance, adjustable features can accommodate various user heights. This customization may seem minor but can make a significant difference in comfort. The angle of the drill can also impact how effectively energy is transferred from the operator to the tool. Misalignment can lead to inefficient drilling and unnecessary wear.

However, not all ergonomic improvements work universally. Different users may have varied needs. Some might find certain grips uncomfortable after extended use. Striking a balance between innovation and practical usability can be challenging but is essential. Continuous feedback from users can help manufacturers refine their designs, ensuring that products serve a broader audience effectively.

Comparative Analysis: Integral Drill Rod vs. Traditional Drill Rods

When comparing integral drill rods to traditional drill rods, several key factors come into play. Integral drill rods are designed as a single piece, which enhances their structural integrity. This means fewer points of failure during drilling operations. Traditional rods, on the other hand, consist of multiple sections. This can lead to complications such as misalignment or joint wear over time.

Integral drill rods often provide better energy transfer. They transmit the drill bit's torque more efficiently. This can result in faster drilling times. However, their rigidity can be a disadvantage in rocky terrains where flexibility is needed. Flexibility in traditional rods allows them to navigate uneven surfaces more adeptly. Yet, this flexibility can sometimes come at the cost of strength.

Maintenance is another aspect worth reflecting upon. Integral rods tend to require less maintenance due to their robust design. However, if damage occurs, repairs can be challenging. Traditional rods, while needing more frequent inspections, can be replaced or repaired section by section. It's a trade-off to consider based on specific drilling environments.

Best Integral Drill Rod Features and Benefits Explained? - Comparative Analysis: Integral Drill Rod vs. Traditional Drill Rods

| Feature/Benefit | Integral Drill Rod | Traditional Drill Rods |

|---|---|---|

| Weight | Lighter due to integrated design | Heavier, separate components |

| Ease of Use | Quicker setup, fewer connections | More complex setup, multiple connections |

| Durability | Generally higher due to robust design | Variable, depending on components used |

| Performance | Improved drilling efficiency | Standard performance, possible efficiency loss |

| Cost Efficiency | Higher initial investment but lower maintenance cost | Lower upfront cost but potential for higher wear and tear |

| Applications | Ideal for tough environments and efficient drilling | Various applications but may face limitations |

| Maintenance | Low maintenance due to fewer parts | Higher maintenance due to multiple parts needing care |

Cost-Effectiveness: Long-term Investment Value in Drilling Operations

When it comes to drilling operations, cost-effectiveness should be a primary consideration. Investing in integral drill rods might seem expensive upfront, but the long-term savings can be substantial. These rods are designed to last longer than traditional options, reducing the frequency of replacements. They withstand high impact and harsh environments. This durability leads to fewer operational disruptions.

Operational efficiency boosts productivity. Less downtime means more work gets done. Additionally, fewer parts translate into reduced maintenance costs. Each component significantly contributes to overall performance. Failing to consider these advantages could lead to costly mistakes. Long-term investment in reliable equipment becomes more apparent over time.

While the initial investment may raise concerns, the value of integral drill rods often justifies the cost. Focusing only on immediate expenses can detract from potential profit increases. Realizing the balance between cost and efficiency is crucial. It's vital to reflect on whether cheaper alternatives truly meet operational needs.

Related Posts

-

Maximizing Efficiency: Why Integral Drill Rods Are Essential for Modern Drilling Techniques

-

10 Best Mining Lamp Chargers: Power Up Your Adventure Efficiently!

-

Understanding the 2025 Top Jack Leg Rock Drill: Features and Applications

-

Best 10 Ventilator Machines You Should Know About

-

How to Choose the Best Led Mining Cap Lamp for Optimal Safety and Efficiency in Underground Operations

-

Top 10 Best Vertical Slurry Pumps for Efficient Slurry Management