What is an Integral Drill Rod? Uses, Benefits, and Types Explained

An Integral Drill Rod is a crucial component in the drilling industry, designed to enhance efficiency and performance in various applications. As a monolithic piece, it offers several advantages over traditional drill rods, such as improved strength and reduced likelihood of failure during operation. This innovation not only streamlines the drilling process but also significantly minimizes the wear and tear associated with multi-piece assemblies.

The uses of Integral Drill Rods are vast and encompass various sectors, including construction, mining, and geological exploration. Their ability to provide reliable and consistent drilling makes them a favored choice among professionals seeking to optimize productivity. Furthermore, the incorporation of advanced materials in the manufacturing process ensures that Integral Drill Rods can withstand extreme conditions, which increases their longevity and effectiveness.

In this article, we will explore the different types of Integral Drill Rods available on the market, their specific applications, and the benefits they bring to various drilling operations. Understanding these facets is essential for industry professionals looking to select the right equipment for their projects, ensuring not only success but also safety in their drilling endeavors.

Definition of an Integral Drill Rod and Its Components

An integral drill rod is a specialized tool used in the drilling industry, characterized by its seamless design and increased durability compared to traditional drill rods. Constructed from high-quality steel, an integral drill rod typically consists of a uniform shaft with a drill bit affixed to one end. This design not only enhances the strength and integrity of the rod but also allows for more efficient drilling in tough geological conditions. According to the International Association of Drilling Contractors, over 60% of drilling operations now utilize integral drill rods to improve performance and reduce downtime.

The key components of an integral drill rod include the body, drill bit, and connection mechanism, which are designed to ensure optimal torque transfer and minimize wear. Integral drill rods are engineered to withstand high pressures and abrasive environments, making them ideal for applications in mining, geothermal energy, and water well drilling. The seamless construction minimizes the risk of mechanical failure, ultimately leading to cost savings and improved project timelines. A recent market analysis by Grand View Research indicates that the global integral drill rod market is projected to grow at a CAGR of 5.2% from 2022 to 2030, highlighting the increasing demand in various sectors.

Tips: When selecting an integral drill rod, consider the specific geology of your drilling site. Different materials and designs may better suit certain conditions, such as soft rock versus hard mineral formations. Additionally, regular maintenance checks can extend the lifespan of your drill rods, maximizing your investment and minimizing operational interruptions.

Integral Drill Rod Types and Their Uses

This chart illustrates the usage frequency of different types of integral drill rods in various applications. As seen, mining is the most significant sector utilizing integral drill rods, followed by aggregate and then geotechnical uses.

Key Uses of Integral Drill Rods in Various Industries

Integral drill rods play a pivotal role in a variety of industries, particularly in mining, construction, and geotechnical applications. These rods are characterized by their solid structure, which allows for greater durability and efficiency compared to conventional threaded rods. According to recent industry reports, the global market for integral drill rods is projected to grow at a CAGR of 5.2% from 2023 to 2028, driven by increasing demand for high-performance drilling equipment in the extraction of minerals and resources.

In the mining sector, integral drill rods are primarily used for underground drilling, blast hole drilling, and exploration drilling. Their robust design ensures a longer lifespan and better performance under high-pressure conditions, which is crucial for optimizing the drilling process. Additionally, in construction, these rods are utilized for rock anchoring and ground stabilization. Reports indicate that effective ground reinforcement methods using integral drill rods can increase the safety and longevity of civil engineering structures, with up to 30% reduction in maintenance costs over their lifecycle.

Geotechnical investigations also benefit from the use of integral drill rods, as they provide reliable drilling capabilities for soil and subsurface testing. These rods help engineers obtain accurate soil samples, which are essential for assessing ground conditions before the design and construction of structures. As noted in various technical studies, the use of integral drill rods has been shown to enhance drilling speed and accuracy, thereby reducing project timelines and improving overall efficiency in various drilling applications.

Benefits of Using Integral Drill Rods Over Traditional Options

Integral drill rods offer several advantages over traditional drilling options that make them increasingly popular in various industries. One of the primary benefits is their strength and durability. Made from a single piece of steel, integral drill rods eliminate the need for welding joints, which can be weak points in traditional drill setups. This solid construction allows for higher resistance to bending and wear, extending the lifespan of the equipment and reducing the frequency of replacements.

Another key advantage is improved efficiency in drilling operations. Integral drill rods are designed to provide better energy transfer and reduced vibration, leading to faster penetration rates. The seamless design helps maintain consistent performance, which can result in lower operational costs and increased productivity. Additionally, because these rods require fewer components and simpler setup processes, they can save valuable time during drilling projects, allowing teams to focus on execution rather than equipment management. Ultimately, the benefits of integral drill rods make them a compelling choice for professionals looking to enhance their drilling operations.

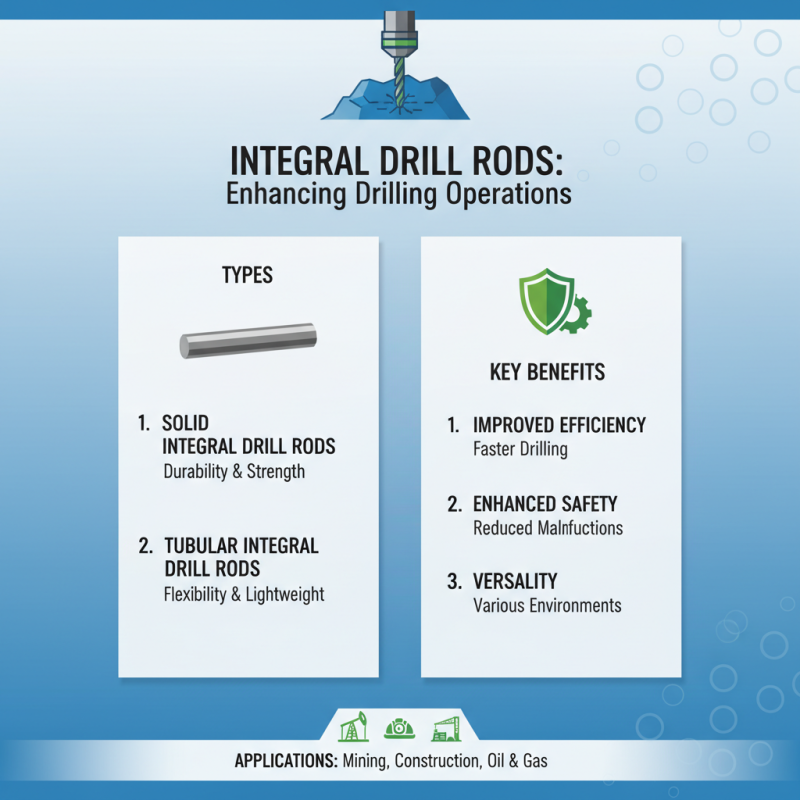

Types of Integral Drill Rods: A Comprehensive Overview

Integral drill rods are vital components in the drilling industry, designed to enhance the efficiency and safety of drilling operations. These rods are categorized into several types based on their construction, intended use, and the drilling environment. The main types include solid integral drill rods, which are known for their durability and strength, and tubular integral drill rods, which offer flexibility and lightweight advantages, making them suitable for various projects.

In addition to these standard types, there are specialized integral drill rods tailored for specific applications. For instance, some versions are specifically designed for use in hard rock conditions, while others are adapted for softer sedimentary formations. Each type of integral drill rod is characterized by different lengths and diameters, allowing for versatility in drilling depths and methods. This comprehensive categorization reflects the diverse needs of the drilling industry, ensuring that professionals can select the most appropriate drill rod for their specific tasks, ultimately optimizing performance and reducing downtime.

Factors to Consider When Choosing an Integral Drill Rod

When selecting an integral drill rod, there are several key factors to consider to ensure optimal performance in various drilling applications. First, the diameter and length of the rod are crucial, as they determine the depth and type of drilling operations it can support. A larger diameter rod may provide higher stability and durability for heavy-duty projects, while a shorter length is typically more suitable for shallow drilling tasks. Evaluating the specific requirements of the project will guide the choice of rod dimensions.

Another important consideration is the material composition of the integral drill rod. High-quality materials such as alloy steel or other specialized metals can significantly affect the rod's wear resistance and longevity. Furthermore, assessing the rod’s weight is essential, as heavier rods may provide better penetration but can be more challenging to handle and maneuver. Additionally, the compatibility of the drill rod with existing equipment and the specific geological conditions of the drilling site should inform the decision, ensuring that the chosen rod will function effectively and efficiently in its intended application.

Related Posts

-

Exploring the Benefits of Portable Ventilators: Your Guide to Respiratory Relief Anytime, Anywhere

-

10 Best Mining Lamp Chargers: Power Up Your Adventure Efficiently!

-

The Ultimate Guide to Choosing the Best Electric Rock Drill for Your Projects

-

How to Choose the Best Led Mining Cap Lamp for Optimal Safety and Efficiency in Underground Operations

-

Unlocking the Darkness: Why Mining LED Headlamps Are Essential for Modern Miners

-

Revolutionizing Water Management with the Latest Mini Submerged Pump Innovations