Top Hand Held Rock Drill Models for Efficient Mining Operations?

In the demanding world of mining operations, efficiency is key. The Hand Held Rock Drill plays a crucial role in achieving that efficiency. Industry expert, John McLaren, emphasizes, "Choosing the right model can revolutionize your drilling process." His insights remind us that not all drills are created equal.

Different models excel in various environments. Some are lightweight, perfect for tight spaces. Others pack power for more extensive projects. Selecting the right Hand Held Rock Drill requires careful consideration. It's easy to overlook specific features that can significantly affect performance.

The right choice can lead to faster projects and less fatigue. Yet, many miners still stick to outdated models. This can slow operations and increase costs. Reflecting on this trend raises questions about upgrading equipment. How often should tools be evaluated? Are current drills still the best option? Efficiency should always be the goal.

Top Hand Held Rock Drill Models for Efficient Mining Operations

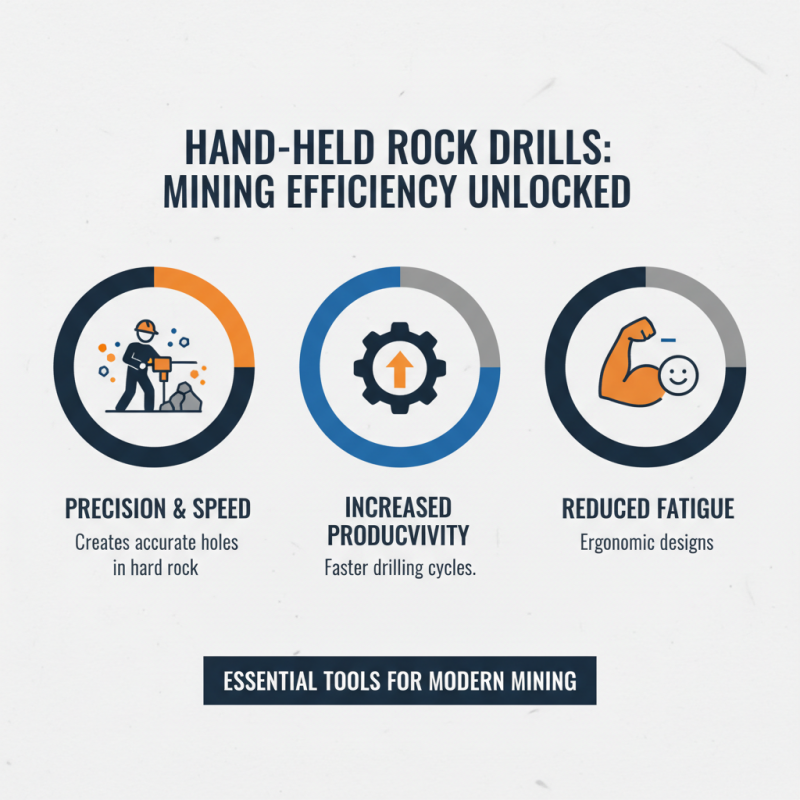

In the world of mining, efficiency is key. Hand-held rock drills have become essential tools for many operations. These devices enable miners to create precise holes in hard rock. The right model can significantly improve productivity and reduce fatigue.

Different models cater to various needs. Some drills are lightweight, allowing for easy maneuverability. Others provide more power, handling tougher rock types. Miners often struggle to find the perfect balance between weight and drill performance. It's important to evaluate what aspects matter most to your specific tasks.

Maintenance can be a challenge. Regular checks are necessary to keep drills in top shape. Neglecting this can lead to equipment failure and downtime. Miners must stay proactive to ensure these drills perform efficiently. Understanding the limitations of each model can help avoid costly mistakes during operations.

Key Features to Consider in Hand Held Rock Drills

When choosing a hand-held rock drill, consider its weight. A lighter model reduces fatigue during long shifts. Operators need stamina to maintain efficiency. However, too light may sacrifice power. Balance is key.

Power and impact energy matter too. Higher impact energy delivers better penetration in tough rocks. Yet, a powerful drill can vibrate more, leading to operator discomfort. Choosing the right settings is crucial for safety and efficiency.

Here are some tips. Maintain drills regularly for optimal performance. Check for worn parts that can affect speed. Use proper personal protective equipment to minimize risks during operation. Always stay aware of your surroundings. Safety starts with awareness and preparation.

Comparison of Leading Brands in Hand Held Rock Drills

When it comes to selecting a hand-held rock drill, efficiency is key. Many models exist, each designed for specific mining needs. The right drill can significantly impact productivity on-site. Features often vary, such as weight, power output, and ease of handling. Some drills are incredibly heavy, making them tough to handle for long periods.

In comparing leading brands, it's essential to look at performance metrics. Some drills offer superior durability, while others excel in speed. Power source can also differ; some are electric, while others run on air pressure. Choosing the wrong type may lead to delays or fatigue.

User reviews reveal varied experiences. Certain models may excel on hard rock but struggle in softer soil. Operators have noted that some drills require frequent maintenance, which can halt work. Each brand has its strengths and weaknesses, which must align with the specific demands of the mining environment. It's crucial to consider these factors thoroughly before making a choice.

Top Hand Held Rock Drill Models for Efficient Mining Operations

| Model | Weight (lbs) | Power Source | Drilling Speed (RPM) | Max Drill Diameter (in) | Price Range (USD) |

|---|---|---|---|---|---|

| Model A | 25 | Electric | 2200 | 3 | $1,500 - $2,000 |

| Model B | 30 | Pneumatic | 2000 | 4 | $1,800 - $2,500 |

| Model C | 28 | Battery | 2400 | 3.5 | $1,200 - $1,700 |

| Model D | 35 | Electric | 2100 | 5 | $2,000 - $2,800 |

| Model E | 22 | Pneumatic | 2300 | 3 | $900 - $1,300 |

Maintenance Tips for Maximizing Rock Drill Performance

Proper maintenance is crucial for maximizing the performance of hand-held rock drills. Regular inspections should be part of the routine. Ensure that all moving parts are lubricated adequately. This not only enhances efficiency but also extends the drill's lifespan. Lack of lubrication can lead to overheating and premature failure. Spare parts should be kept on hand. Unexpected breakdowns can halt projects. Dealing with delays creates frustration and increased costs.

In addition, cleanliness cannot be overlooked. Dust and debris accumulate in tight spaces. Regularly cleaning the drill helps maintain optimal performance. Simple actions, like using a compressed air tool, can make a difference. Pay attention to wear and tear. Components such as drill bits should be replaced when they show signs of damage. Waiting too long can affect the entire operation's efficiency.

Moreover, operators should be trained to spot irregularities. A sudden change in drilling speed could indicate a problem. Quick diagnostics can save time and resources. Sometimes, issues arise from improper handling rather than equipment failure. Training sessions can improve overall performance. Even seasoned workers may need reminders on best practices. Small mistakes can lead to significant setbacks. Adjusting to feedback is essential for ongoing improvement.

Innovative Technologies Enhancing Hand Held Rock Drilling Efficiency

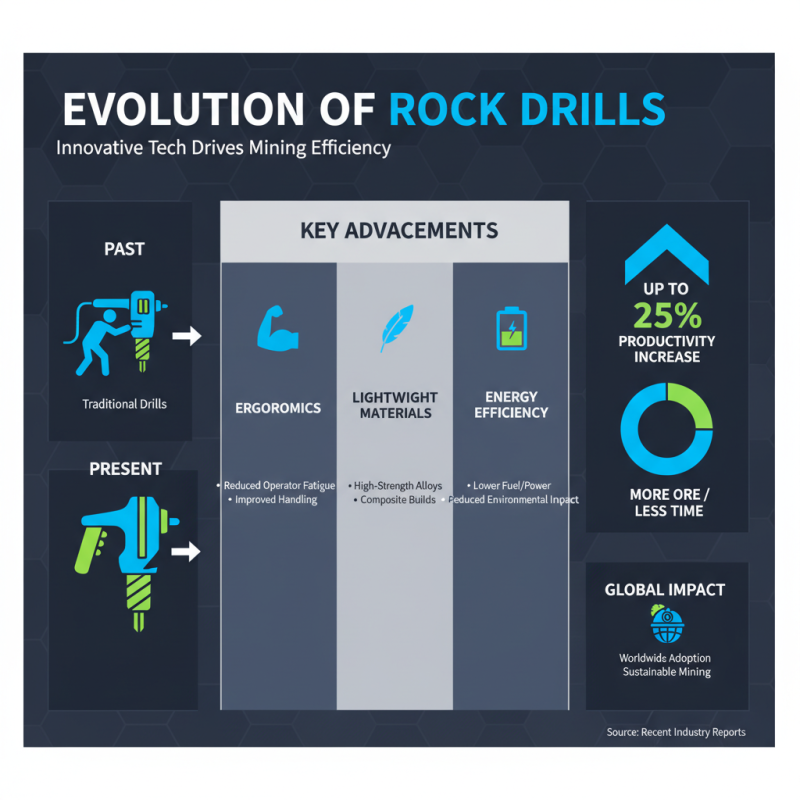

Hand held rock drills have evolved significantly. Innovative technologies are driving efficiency in mining operations worldwide. According to recent industry reports, modern drilling equipment can increase productivity by up to 25%. This surge is a result of advancements such as better ergonomics, lightweight materials, and improved energy efficiency.

Operators can now enjoy optimized drilling speeds and reduced fatigue. New drill models feature smart sensors that monitor performance in real-time. This allows for immediate feedback, enhancing operational decision-making. Industry analysis shows that companies embracing these technologies can expect shorter project timelines and lower operational costs. However, not all workers adapt easily. Training is essential to maximize these benefits.

Tips: Always consider the weight and balance of a drill. A comfortable grip minimizes operator fatigue.Optimize drill settings for specific rock types. Tailoring your drill can greatly improve performance. Lastly, maintain your equipment regularly. A well-maintained drill performs significantly better than an overlooked one.

Related Posts

-

Top 10 Hand Held Rock Drills of 2025: Your Ultimate Buying Guide

-

2025 Top Jack Leg Rock Drill Innovations: Features and Best Practices

-

What is an Integral Drill Rod? Uses, Benefits, and Types Explained

-

Understanding the 2025 Top Jack Leg Rock Drill: Features and Applications

-

Top 10 Benefits of Using a Jack Leg Rock Drill?

-

Top 10 Electric Rock Drills for Efficient Demolition and Construction