Top Mining Slurry Pumps of 2025: Features, Benefits, and Buying Guide

The mining industry is continually evolving, driven by advancements in technology and the increasing demands for efficient resource extraction. Among the critical equipment used in this sector, Mining Slurry Pumps play a vital role in transporting the slurry mixtures of solid and liquid materials across various mining operations. As we look ahead to 2025, understanding the features and benefits of the top mining slurry pumps becomes essential for stakeholders aiming to optimize their operations.

In this comprehensive guide, we will explore the latest innovations and enhancements in mining slurry pump technology, highlighting how these advancements can lead to improved performance and reduced operational costs. By examining key factors such as pump design, material selection, and energy efficiency, we aim to provide valuable insights for those looking to invest in or upgrade their mining slurry pump systems. Whether you are a seasoned professional in the mining sector or a newcomer seeking reliable information, this guide is designed to equip you with the knowledge needed to make informed purchasing decisions for your mining endeavors.

Overview of Mining Slurry Pumps and Their Importance in 2025

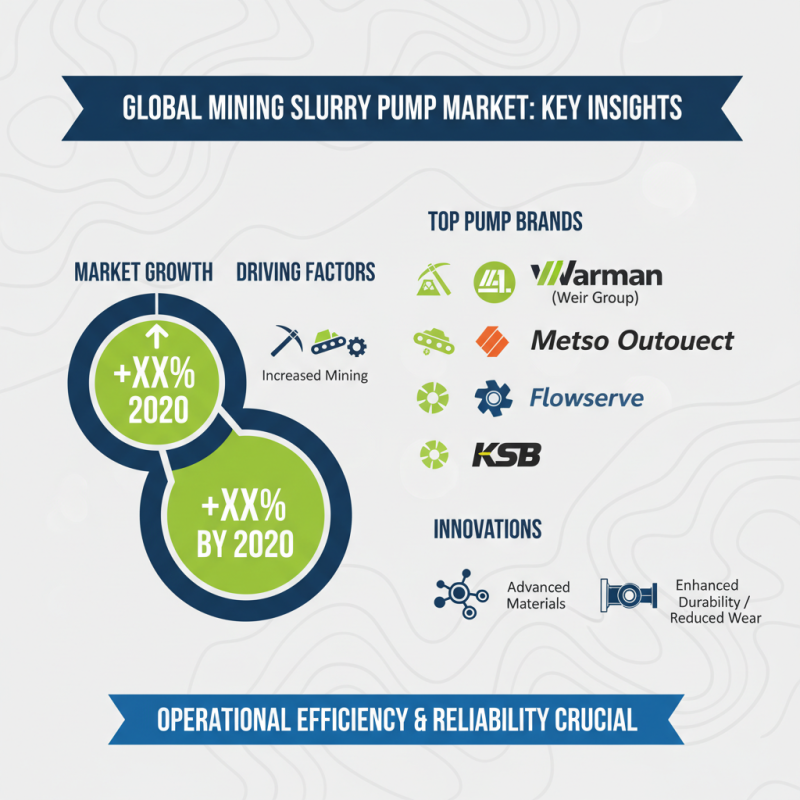

Mining slurry pumps play a crucial role in the mining industry, particularly in the efficient handling of slurry, which is a mixture of water and mineral particles. As we approach 2025, the demand for advanced slurry pumping systems is projected to grow significantly, driven by the increasing production rates in the mining sector and the need for improved operational efficiency. According to a recent market analysis by Allied Market Research, the global slurry pumps market is expected to reach a valuation of approximately $8 billion by 2025, with a compound annual growth rate (CAGR) of around 5.3%. This growth underscores the vital importance of slurry pumps in managing the complexities of transporting materials in harsh mining environments.

The significance of mining slurry pumps extends beyond mere transport. They are engineered to handle various challenges, including high solid contents, erosive materials, and fluctuating flow rates. In 2025, innovations in materials science are expected to enhance the durability and performance of these pumps, resulting in lower maintenance costs and increased operational uptime. For instance, advances in wear-resistant coatings and pump designs are anticipated to extend the lifespan of slurry pumps, which can be a critical factor in optimizing overall mining operations. Industry experts predict that adopting these innovations will not only lead to cost savings but also improve the environmental sustainability of mining processes by reducing the energy consumption associated with pumping systems.

Top Mining Slurry Pumps of 2025: Features, Benefits, and Buying Guide

| Pump Model | Max Flow Rate (m³/h) | Max Head (m) | Material | Efficiency (%) | Weight (kg) | Price Range ($) |

|---|---|---|---|---|---|---|

| Model A | 150 | 50 | Steel | 85 | 200 | 5000 - 7000 |

| Model B | 180 | 60 | Cast Iron | 90 | 250 | 7000 - 9000 |

| Model C | 200 | 70 | Ceramic | 92 | 300 | 9000 - 11000 |

| Model D | 220 | 80 | Polymer | 88 | 350 | 8000 - 10000 |

| Model E | 250 | 90 | Stainless Steel | 95 | 400 | 12000 - 14000 |

Key Features to Look for in Modern Mining Slurry Pumps

When selecting a modern mining slurry pump, certain key features can greatly enhance performance and reliability. First, consider the pump materials used in construction. High-quality alloys and elastomers are essential for durability, given the abrasive nature of mining slurries. Selecting a pump that incorporates wear-resistant materials will reduce downtime and maintenance costs over time.

Another important feature is the pump design, which should facilitate efficient handling of high-viscosity liquids. Look for pumps with a self-priming capability and adjustable impeller settings. These features ensure optimal performance under varying conditions and can improve the overall efficiency of the mineral processing operation.

Tips: Always evaluate the flow rate and head capabilities of the slurry pump to match the specific requirements of your mining operation. Additionally, consider the ease of maintenance and availability of spare parts, as both can significantly impact the long-term operational costs. Lastly, selecting a pump with integrated monitoring systems can provide real-time data on performance, helping to preempt any issues before they escalate.

Top Mining Slurry Pumps of 2025: Performance Comparison

This chart compares the flow rates of the top mining slurry pumps of 2025, highlighting their respective performance in m³/h. When selecting a slurry pump, consider the flow rate as a critical factor for your mining operations.

Benefits of Upgrading to Advanced Mining Slurry Pumps in 2025

Upgrading to advanced mining slurry pumps in 2025 can offer significant benefits that enhance operational efficiency and reduce costs. According to a recent report by Global Market Insights, the mining slurry pump market is expected to grow at a CAGR of over 5.5% through 2025, driven by the demand for efficient and durable pump solutions. Modern slurry pumps are designed with advanced materials and technologies that improve wear resistance and minimize maintenance downtime. These innovations result in longer service life and improved reliability, which are critical in harsh mining environments where failure can lead to costly production halts.

In addition to durability, advanced mining slurry pumps provide improved hydraulic performance. This has been quantitatively assessed in several industry studies, indicating that newer pump designs can enhance overall energy efficiency by up to 15%. Enhanced energy efficiency translates to lower operational costs and reduced environmental impact, making these pumps not only a more sustainable option but also a more economical one for mining operations. The ability to handle abrasive slurries more effectively also ensures better performance in transporting materials, leading to improved productivity and output in mining processes. Investing in these advanced systems is not just a choice but a strategic move towards optimizing the longevity and efficiency of mining operations.

Top Brands and Models of Mining Slurry Pumps to Consider

When selecting a mining slurry pump, understanding the top brands and models available in the market is crucial for ensuring operational efficiency and reliability. According to a recent industry report from the Global Mining Pump Market, the slurry pump segment is expected to witness substantial growth, driven by increasing mining activities and the demand for efficient material handling. Key players in the market are innovating with advanced materials and designs that enhance durability and reduce wear, offering significant benefits in harsh mining conditions.

Leading models typically feature robust construction to handle abrasive and corrosive materials, along with efficient hydraulic designs that optimize flow rates. For instance, pumps with high chrome and rubber lining options are popular for their ability to withstand the rigors of mining environments, thereby extending service life and minimizing operational costs. Data reveals that pumps with an efficiency rate of over 80% are increasingly favored, as they contribute to cost savings and improved throughput in mining operations.

Additionally, the integration of smart technology in modern slurry pumps allows for enhanced monitoring and control, ensuring that operators can respond swiftly to any performance issues. This technological advancement is becoming a standard feature in many high-performing brands, aligning with the industry’s push toward automation and data-driven decisions. As mining companies continue to modernize their fleets, the selection of slurry pumps with these innovative features will be critical in maintaining competitive advantage in a rapidly evolving market.

Comprehensive Buying Guide for Selecting the Right Slurry Pump

When selecting the right slurry pump, it’s crucial to consider several key factors that can significantly impact both performance and efficiency. Begin by assessing the type of slurry you will be handling, as the pump must be compatible with the specific density, viscosity, and size of the solid particles within the mixture. This ensures optimal operation without causing undue wear or damage to the pump components.

Another important feature to evaluate is the pump's construction materials. Slurry pumps are exposed to abrasive materials and corrosive environments, so opting for robust materials such as hardened alloys or rubber linings will enhance durability and longevity. Additionally, consider the pump's design—options like centrifugal or positive displacement pumps cater to different operational needs.

Tips: Always verify the pump's specifications against your site's requirements. Perform calculations to determine the required flow rate and head pressure to ensure efficient pumping. Don’t hesitate to consult with experts in the field to gain insights into the latest technologies and designs available. Balancing these considerations will lead you to a slurry pump that meets your operational standards while providing reliability and efficiency.

Related Posts

-

Discover the Best Mining Led Headlamp for Your Underground Adventures

-

7 Essential Tips for Choosing the Right Ventilation Machine for Your Home

-

Top 5 Mining Jack Hammers for Efficient Rock Breaking and Drilling

-

The Ultimate Guide to Choosing the Best Electric Rock Drill for Your Projects

-

Innovative Safety Mining Lamp Solutions Enhancing Worker Protection in Harsh Environments

-

10 Best Mining Lamp Chargers: Power Up Your Adventure Efficiently!